- news

- AMD Radeon Pro Duo with LiquidVR

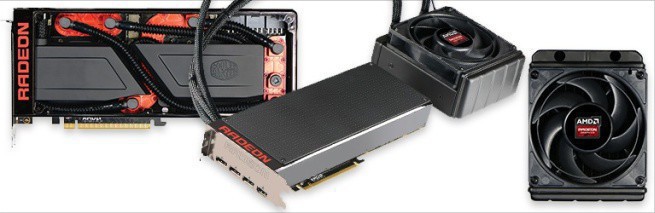

AMD Radeon Pro Duo with LiquidVR

The AMD Radeon Pro Duo, along with the LiquidVR SDK, is a platform designed for a variety of VR applications: from entertainment, education, reporting, to medicine and cinema. With 16 teraflops of processing power, developers can prepare VR materials faster, as well as run DirectX 12 games.

The new AMD Radeon Pro Duo graphics card is equipped with two graphics chips. This is the first product from the AMD VR ready creator line. Along with LiquidVR, the SDK is also Crytek’s choice for the VR first initiative, which aims to help educate new VR talent by providing the right equipment to schools and universities around the world.

The AMD Radeon Pro Duo graphics card will be available at the beginning of the second quarter of 2016 in online stores at the suggested price of $ 1499.

CONTACTS

Address

1A Sportyvna sq, Kyiv, Ukraine 01023

804 NE 125th St, Miami, FL 33161

info@servreality.com

Skype

info@servreality.com